|

So, when I got the HV-Pro board the enclosures weren't ready. I wanted the

unit in approximately the same place that the old HV was so that I

wouldn't have to re-route wires. I mounted some standoffs to the board and

attached some wire to the two on the top of the board. The wire was then

looped and screwed to the wall. Quick and easy, but hardly neat; and

definitely left something to be desired in the wire management department.

When I moved into this house I decided to mount my HV

in a larger enclosure than the one it came in. HV-Pro was originally

going to come with an enclosure that was almost exactly the same size as

the one I had the old HV mounted in. But some ideas were thrown around the

e-mail list, and the enclosure was redesigned to be bigger. I could have

made this work, but it would have required some major reworking of my

closet, and I realized that I liked the bottom hinge of my current

enclosure. So the solution was to modify it for HV-Pro.

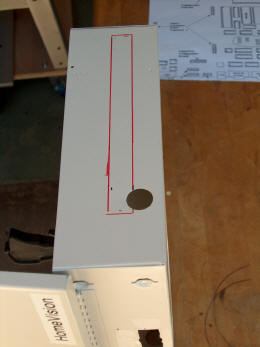

The modification was based on the original picture of HV-Pro

in its enclosure on CSIís website. First I marked off the position of

the new slots with a Sharpie. I was a little worried that removing so much

material was going to affect the integrity of the enclosure. It turns out

that it did, but once the thing is screwed to the wall everything is fine.

With the slots marked out I decided I wanted to add a little window to the

door so I could see the status LEDs. I had considered cutting two more

slots out of the door so I could see the I/O lights as well. But decided

that would mean removing a little too much material.

After it was marked I took my jig saw to it and began

to make the loudest cuts I have ever made in my life. Even through the ear

protection I was glad I didnít have to cut any more than I did. Cutting

the 90į corners was a little tough. But with multiple jig saw cuts and a

nibbler I was able to do a pretty decent job. Just a quick pass with the

Dremel to grind down the sharp edge and I was ready to paint.

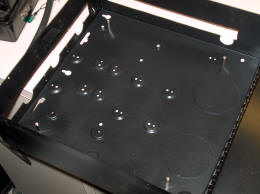

I chose black for no reason other than I already had

it. And the recently discarded table saw box made for a quick spray booth.

Once the paint dried, all that was left was to mount the standoffs [all

four lined up correctly on the first try Ė I was shocked], and glue a

little piece of Plexiglas for the window. Remount the lock, and Iím

done.

|

HV-Pro and MFEB before enclosure.

Laying out wire slots.

All slots cut. The window on the front is for the

status LEDs.

Painting. Good thing I just bought a new table saw.

Mounting the standoffs. |